Aectual was recently featured in a long-form article as a part of Forbes’ Innovation column. The piece deep dives into the disruptive potential of Aectual’s 3D printing process to create architectural elements and interior products that are unique, accessible, and affordable.

With a focus on individual building products such as flooring, wall panels, or façade cladding, Aectual’s strategic production approach brings about significant reductions in speed and cost without compromising on design quality.

Hedwig Heinsman, co-founder and Chief Commercial Officer of Aectual, says that, unlike entire homes, architectural products can be used in any building worldwide, whether those buildings are new or rebuilt.

"It is easy to digitally adapt them for different local conditions and regulations because our products are built up from smart datasets which make Aectual's platform and products scalable."

Aectual cuts down costs and brings design into the masses

Sasha Wedekind, a research analyst with Guidehouse Insights, said that overall, the whole (3D) industry is not yet very mature and is more focused on what can be.

“However, there are more and more case studies each year of successful projects, and things are ramping up quickly,” said Wedekind. “There are many early adopters because cost reductions and construction speed have a huge appeal to customers. That is the appeal across 3D for construction, including interior products.”

“Products like Aectual’s significantly cut down costs and can bring design “into the masses,” which I think is very appealing to consumers,” said Wedekind.

“We have seen that with all sorts of personalization products that are out there. Products like Aectual’s are meeting the need for unique, accessible, and affordable interior designs with 3D printing as the enabler.”

3D printing has the potential to revolutionize construction

Guidehouse released its 3D Printing for Residential and Commercial Construction report in January 2021, which notes that cost savings, reduced construction time, and sustainability compared with traditional construction are the most significant drivers for the market.

The report says construction in 3D-printed buildings is expected to grow from $6.5 Million in 2020 to $264 Million in 2029 at a 51% compound annual growth rate.

Wedekind believes that considering the current tight construction margins and labor shortages, 3D printing has the potential to revolutionize construction and unlock new markets to the industry, such as affordable homes.

“I see a lot of potential in 3D printing in construction beyond building envelope, specifically in finishing and architectural elements, such as stairs, flooring systems, ceiling systems, etc.,” added Wedekind.

“3D printing has the potential to democratize design in these product categories, enabling designers and customers to create unique features in their home/building at a fraction of a cost of custom features today.

Unique architectural pieces at any scale

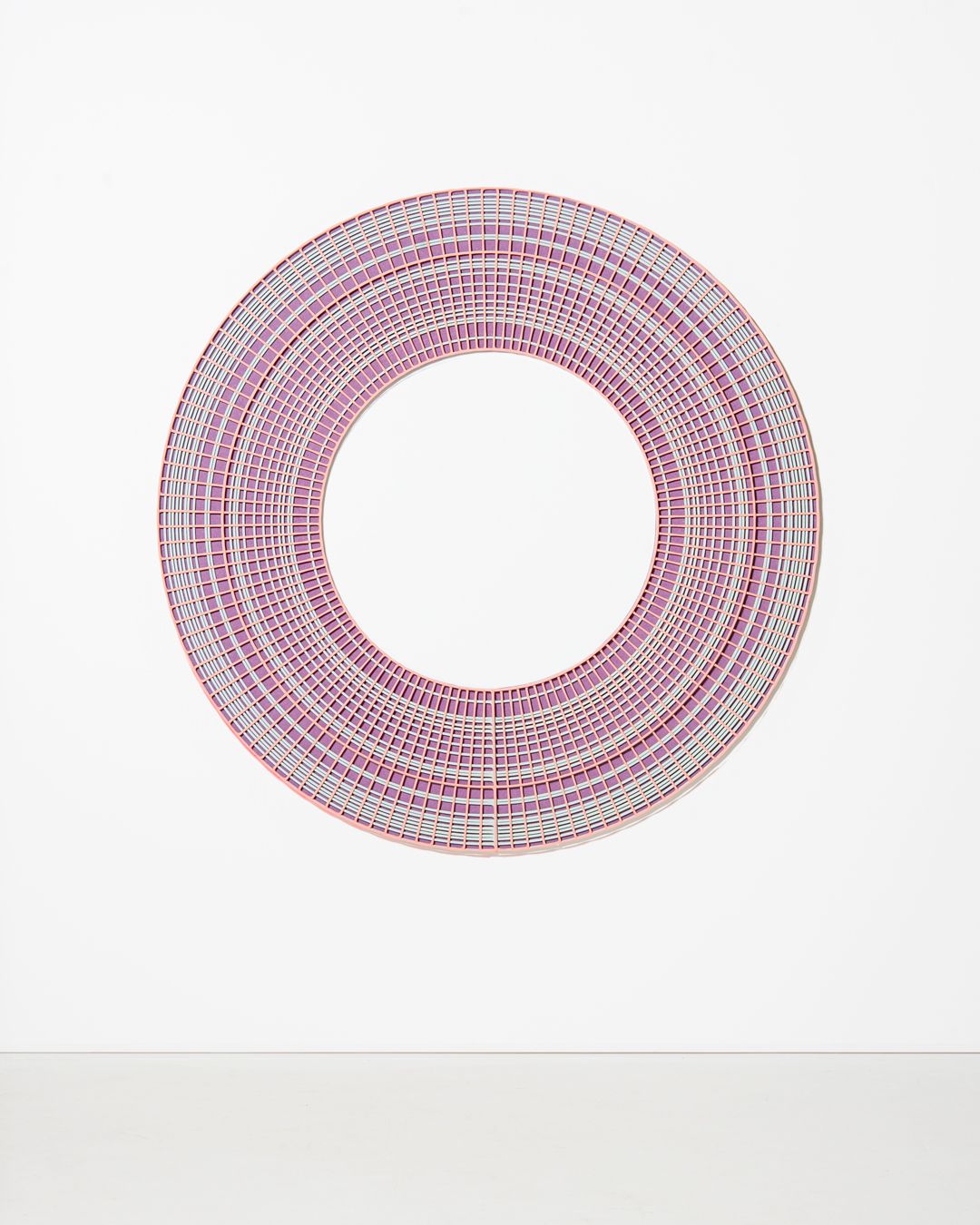

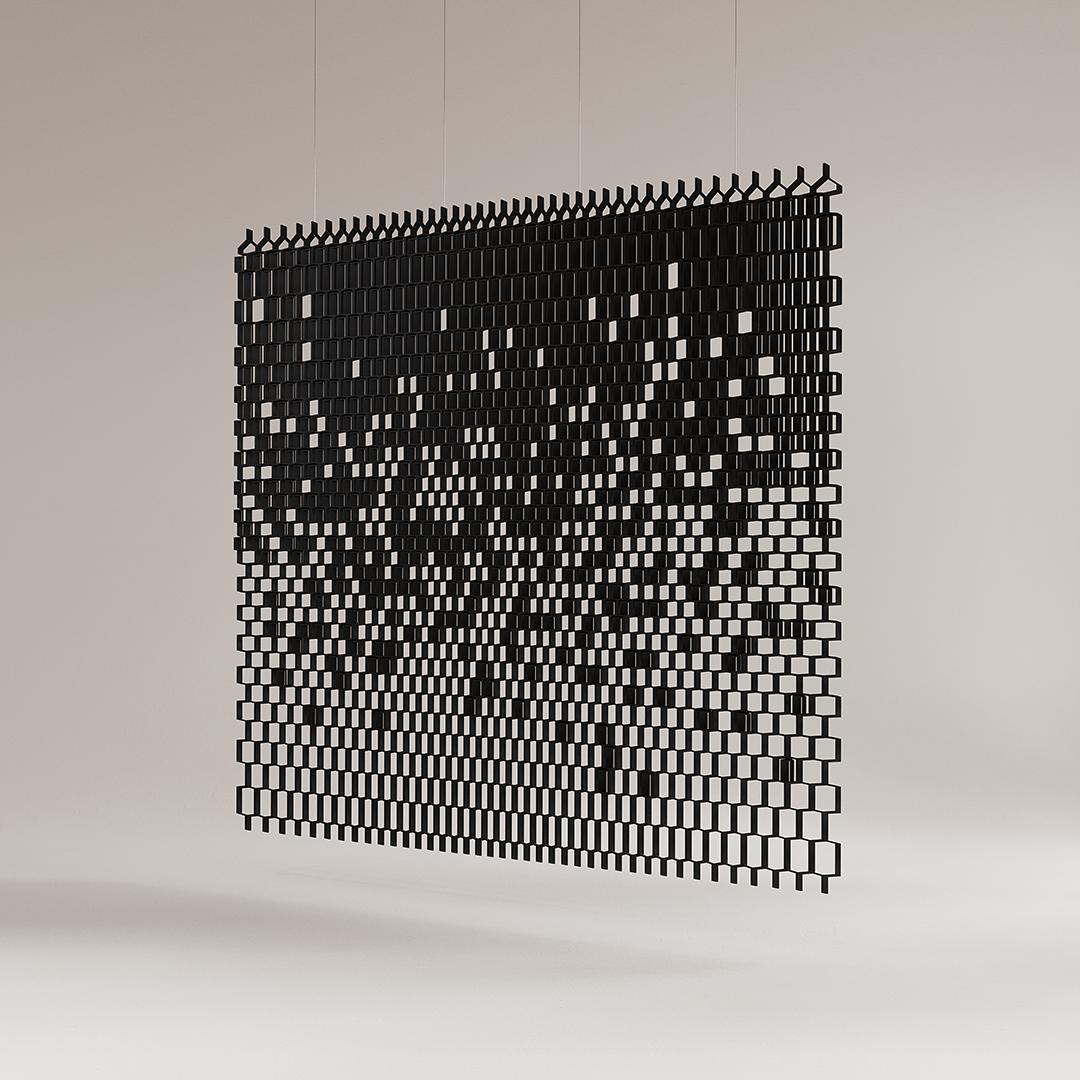

One of the most exciting benefits of Aectual’s 3D printing technology is that it enables anyone to create completely unique architectural pieces at any scale. Aectual’s approach embraces the opportunities that digital fabrication offers to be more responsive to consumer needs and demands.

The company's platform uses customizable engineered parametric products, a design dashboard, and proprietary robotic XL 3D-print technology to allow users to upload and create their product versions. Users can also visit the Aectual website and select an architectural feature to customize. Once the feature is ordered, Aectual 3D-prints and installs the product.

But, Aectual's 3D printing robot also has a more significant world issue on its agenda - to change architecture, city, and community building to make living environments more healthy, affordable, and personal.

Bringing CO2 emissions back to zero

"The architecture, engineering, and construction sector are now responsible for 39% of all CO2 emissions," said Heinsman. "We can bring that back to zero, with building products that are fully recyclable and circular, and materials that can even be leased instead of discarded.

"Companies can easily create bespoke, 100% circular architectural products that don't harm the planet. Architects have ultimate design freedom and can directly share and sell their designs to the entire world," added Heinsman.

"Ultimately, it will democratize architecture — making qualitative architecture and design available to everyone."

The company has several 3D printed architectural features in international commercial real estate projects, including flooring in Amsterdam Schiphol International Airport, printed display walls in Nike Town London, and flooring at Capital C offices in Amsterdam that uses recycled Budweiser bottles.

Aectual: Sustainable 3D printed architecture made easy

The world’s first Platform for mass customizable, 100% Circular, 3D-printed XL architectural and interior products.

Aectual is a design-to-delivery platform that enables rapid production of beautifully designed, high quality, 3D-printed architectural and interior products, like terrazzo artwork flooring, fixtures, wall paneling, columns, façades, stairs, room dividers, planters, and table screens — all made from 100% recycled, sustainable materials.

Get in touch by email or phone and we'll be happy to give you instant feedback about all possibilities for your project.

Phone:

Email:

Source: Forbes