Aectual’s 3D Printing Technology: Pioneering Local Manufacturing for a Sustainable Future

In the rapidly evolving world of additive manufacturing, Aectual is leading the charge with its groundbreaking XL 3D printing technology. By pushing the boundaries of design and production, Aectual is not only transforming the landscape of interior and architectural products but also setting a new standard for sustainability and efficiency. Our advanced 3D printing system, combined with strategic global partnerships, is fueling an ambitious international expansion. This approach enables us to meet the growing demand for large-scale, customized solutions while supporting our mission to establish local manufacturing hubs worldwide, reducing environmental impact and fostering innovation on a global scale.

Local Manufacturing for a Better Planet

At Aectual, we believe that the future of manufacturing is local. By producing goods closer to the end-user, we significantly reduce carbon emissions associated with transportation and minimize waste through precise, on-demand production. Our vision is to expand our network of local manufacturing facilities globally, enabling us to deliver high-quality, sustainable products while supporting local economies. This approach not only benefits the environment but also fosters innovation and customization tailored to regional needs.

One of the Largest Production Facilities in Europe

To meet the rapidly growing demand for sustainable, large-scale 3D-printed products, Aectual sought an efficient way to scale its production. This led to a strategic joint venture with HB3D in the Netherlands, a partnership that has significantly enhanced both companies' ability to serve an expanding market and achieve their growth ambitions.

By the end of 2023, both companies combined their expertise and resources to establish a joint production venture: one of the largest 3D printing production facilities in Europe. Leveraging faster-printing robots and a highly automated process, the facility has achieved a remarkable 300% increase in production capacity within just one year. Operating 24/7, this cutting-edge facility enables the rapid fulfillment of large orders, while also driving the development of innovative techniques and a sustainable material portfolio.

This collaboration not only boosts production capacity but also strengthens our market position. Our partner brings specialized expertise in creating complex products such as boat hulls, bridge sections, and statues, while Aectual leads in 3D-printed circular interior and architectural applications, producing facades, wall panels, ceilings, and furniture for renowned international clients like Tiffany & Co., Hermès, Nike, and TetraPak. This partnership exemplifies how combining technological innovation with sustainable practices can redefine the future of manufacturing.

Amsterdam: The 3D Print Capital

Aectual has established its headquarters, XL 3D print lab, and materials bank in the Bajeskwartier area of Amsterdam. This location will soon feature a large showroom, set to open in 2025, dedicated to showcasing our innovative products and welcoming international clients. The Bajeskwartier hub emphasizes product development and client engagement while also providing space to further professionalize our Circular Take-back service. Complementing this, is the joint production facility in Amsterdam Oost's Amstelkwartier. This facility merges technological expertise into one dynamic space, significantly enhancing our production capabilities.

Our Advanced Technology: A Game Changer in XL 3D Printing

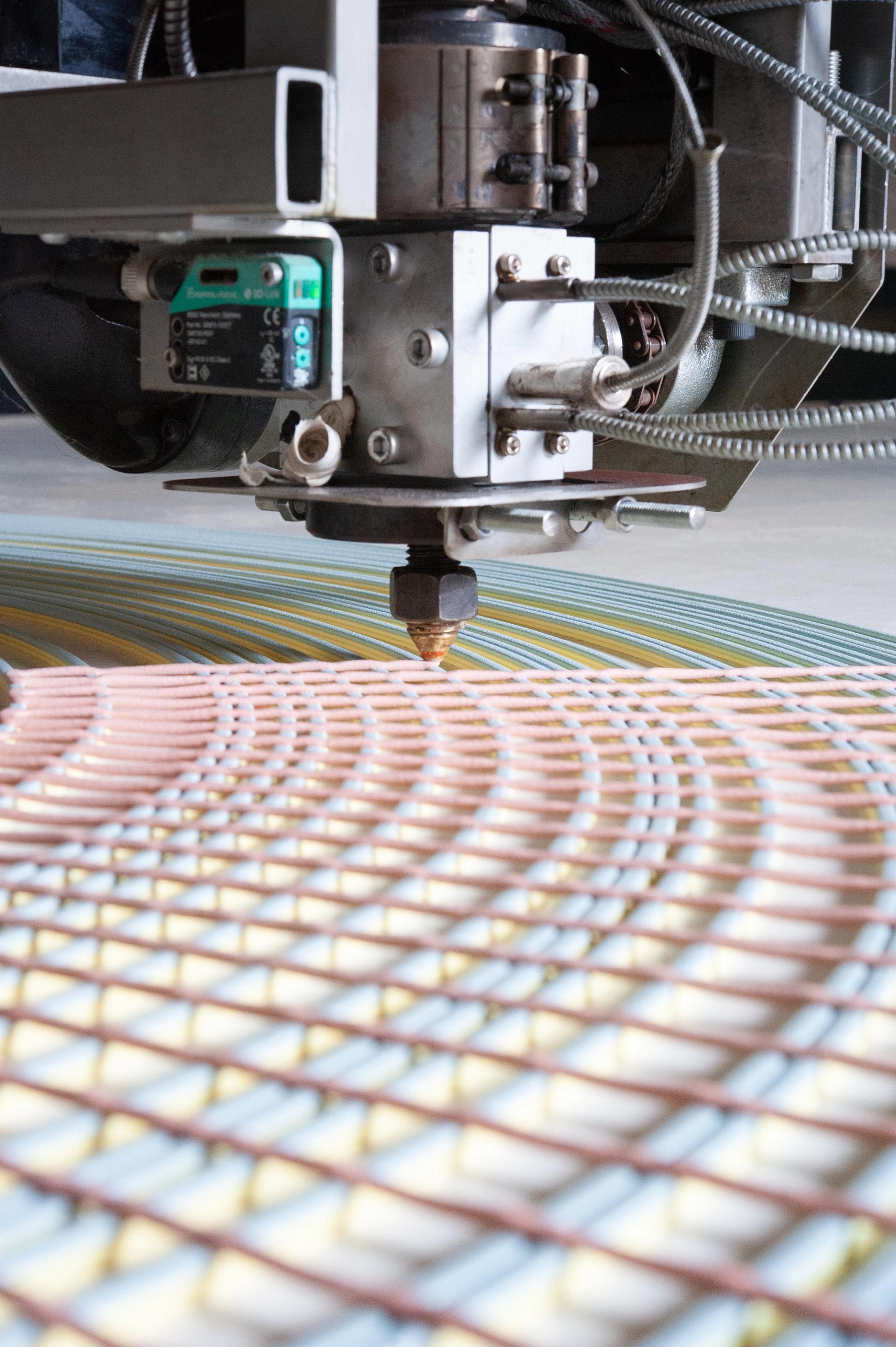

At the heart of Aectual’s success is our in-house developed XL 3D printing technology, which sets new standards in the industry. Our advanced system utilizes Fused Granular Fabrication (FGF) based on Pellet Extrusion mounted on robotic arms. This innovative method connects a comprehensive industrial network capable of continuous, around-the-clock production.

Key Features of Aectual’s XL 3D Printing System:

Large-Scale Robot Arms: Equipped with 6-axis industrial robot arms and an additional 7th axis track extending up to 9 meters, our system boasts a massive print-bed volume of approximately 170 m³, allowing for the creation of large, complex structures.

High-Capacity Extruder Technology: Our unique extruder system, directly mounted on the robot arm, ensures precise temperature control and superior material quality. This setup enables fine-tuned adjustments of print line thicknesses and heights, resulting in high-resolution outputs.

Smart, Integrated Control Systems: We’ve extensively upgraded our control systems to enhance motion accuracy, print queue management, and smart features. Our platform facilitates seamless communication between the robot, extruder, and control systems, enabling remote monitoring and online control for maximum efficiency.

Digital Factory & Smart Learning: The complete digitization of our design and production processes eliminates the need for manual data exchanges, reducing errors and streamlining workflows. All data is stored in a centralized, searchable database, fostering a paperless, efficient, and accurate production environment.

Blueprint for International Expansion

Aectual’s production joint venture is not just a partnership; it’s a blueprint for global growth. Reflecting on a year of successful teamwork, we’ve demonstrated how combining expertise in circular design and robotic printing can accelerate market growth and innovation. This strategic alliance has enabled us to better meet the growing demand for sustainable solutions while paving the way for future international facilities.

Hans Vermeulen, Co-founder and CEO of Aectual, remarks, “This partnership marks a significant milestone in our international expansion. It serves as a model for future production facilities in other countries, allowing us to produce locally for global clients.” New Aectual partnerships in Germany and elshewhere are in an advanced stage.

Join the Aectual Movement

At Aectual, we believe in the power of partnerships and ecosystems. We invite you to connect with our platform and contribute to the future of sustainable manufacturing. Whether by integrating your XL 3D print capacity or adopting our in-house developed industrial XL 3D print system, there are numerous opportunities to collaborate and innovate together.

Get in touch with us to learn more about becoming a partner and joining the Aectual movement towards a better, greener planet.

Together, let’s shape the future of 3D printing and sustainable manufacturing, one layer at a time.